上海城兰贸易有限公司

主营:明事达+丽雅迪+单组份胶+双组份胶+硅酮耐侯胶+硅酮结构胶+硅酮玻璃胶+汽硅酮车密封胶+硅酮特种胶+硅酮电子胶+中性硅酮耐侯密封胶+中性硅酮防霉胶+中性硅酮结构胶+大板块玻璃专用胶+高档门窗专用胶+酸性硅酮玻璃胶+高

主营:明事达+丽雅迪+单组份胶+双组份胶+硅酮耐侯胶+硅酮结构胶+硅酮玻璃胶+汽硅酮车密封胶+硅酮特种胶+硅酮电子胶+中性硅酮耐侯密封胶+中性硅酮防霉胶+中性硅酮结构胶+大板块玻璃专用胶+高档门窗专用胶+酸性硅酮玻璃胶+高

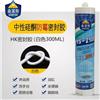

| 品牌: | 明事达 | 型号: |

| 拉伸强度:0.68(MPa) | 产地:中国 | 品牌:明事达 |

MSD-3300 | NEUTRAL SILCONE WEATHER RESISTANCE SEALANT ADHESIVE |

PRODUCT FEATURES

|

MAIN APPLICATION:Seam filling and seal for all kinds of door and window installation and roof construction, aluminum composite panels, metal, stone, plastic; other many building and industry application

CRITERION ACCORD WITH:National Standard GB/T 14683-2003, Industry Standard JC/T882-2001

COLOR:Clear, black, grey, white and other custom colors

PACKAGE:300ml plastic tube, 590ml composite film soft package

EXECUTION METHOD:Please refer to <MOSIKA SILCONE CONSTRUCTION SEAL ADHESIVE USE TECHNOLOGY GUIDE>

USE RESTRICTION:

Don’t use on structural cementation

Don’t use on the occasions contact with alkaline material such as marble, granite and etc.

Don’t use on the surface which is easily to exudate oil or with plasticizer

Don’t use on impenetrable occasions because silicone adhesive needs absorb moisture from the air to solidify

Don’t use on the surface which is frosted or humid or in the water continuously or wet year-round

It can’t be used if the material surface temperature is lower than 4℃or higher than 40℃

TECHNOLOGY INDEX

TEST ITEMS | NATIONAL STANDARD GB/T 14683-2003 | INDUSTRY STANDARD JC/T882-2001 | ACTUAL TEST VALUE | TEST ACCORD WITH |

Prolapse degree (mm) | ≤3 | ≤3 | 0 | GB/T 13477 |

Extrusion performance (Ml/min) | ≥80 | ≥300 | 780 | |

Surface dry time (min) | ≤180 | ≤120 | 10 | |

Hardness (hsA) | ∕ | ∕ | 50 | GB/T 531 |

Heat weightlessness % | ≤10 | ≤10 | 5.0 | GB/T13477 |

Stretch recovery % | ≥80 | ≥80 | 90 | |

Tensile Strength Map standard condition | ≥0.4 | ≥0.4 | 0.68 | |

Stretch cohere standard condition | NO DAMAGE | NO DAMAGE | NO DAMAGE | |

Stretch cohere UV exposure | NO DAMAGE | NO DAMAGE | NO DAMAGE | |

Stretch cohere under heat press and cold stretch | NO DAMAGE | NO DAMAGE | NO DAMAGE | |

Stretch cohere after dip in water | NO DAMAGE | NO DAMAGE | NO DAMAGE | |

Stretch cohere after dip in water and light | NO DAMAGE | NO DAMAGE | NO DAMAGE | |

Displacement % | ±20 | ±20 | ±20 | ASTMC719 |

Biggest strength elongation % | ∕ | ∕ | 180 | GB/T13477 |

Storage period | Store temperature between 5-27℃, condition relative humidity less than 50%, 9 months from the production date | |||